Danfoss inverter service

We provide service and remanufacturing of Danfoss inverters. We service components from series such as iC7 drives, FC-102, FC-202, FC-301, FC-302, MCD-201, MCD-202, VLT AQUA Drive, VLT FCD 300, VLT FCM 300, VLT FCM 106 VLT2800, VLT 3000, VLT 3500, VLT5000, VLT 6000 and VLT 8000.

Call

Neethsel HK provides fast service for Danfoss inverters offering services such as:

- Danfoss inverter diagnostics

- Fast repair of Danfoss inverters

- Danfoss inverter service

- Danfoss inverter reconditioning

- Functional testing of Danfoss inverters

Danfoss inverter diagnostics

Express repair of Danfoss inverter

Danfoss inverter functional tests

What sets Neethsel HK service apart

Our strength is specialized service of Danfoss inverters, carried out with the use of modern technological solutions and with emphasis on fast, efficient and timely service. As part of our offer, we provide:

- High quality spare parts available in our warehouse in Hong Kong

- Functional testing of Danfoss inverters on dedicated test benches

- Express inverter service up to 1 day

- Reconditioning of equipment taken out of production

- Warranty for repairs up to 24 months

- Serving customers from Hong Kong, Europe and around the world

Danfoss 30kw inverter – quick diagnostics and repair

Fill out the “Request Repair” form, and we will expressly diagnose and repair your defective inverter.

Hotline Service: +852-3008 7967

Email: [email protected]

Damage identification and repair process for Danfoss inverters:

- Verification of electronic circuits

- Identification of defective components

- Replacement or reconditioning of components

- Setting the operating parameters

- Detection of invalid resolver signals

Danfoss frequency inverters undergo thorough functional testing:

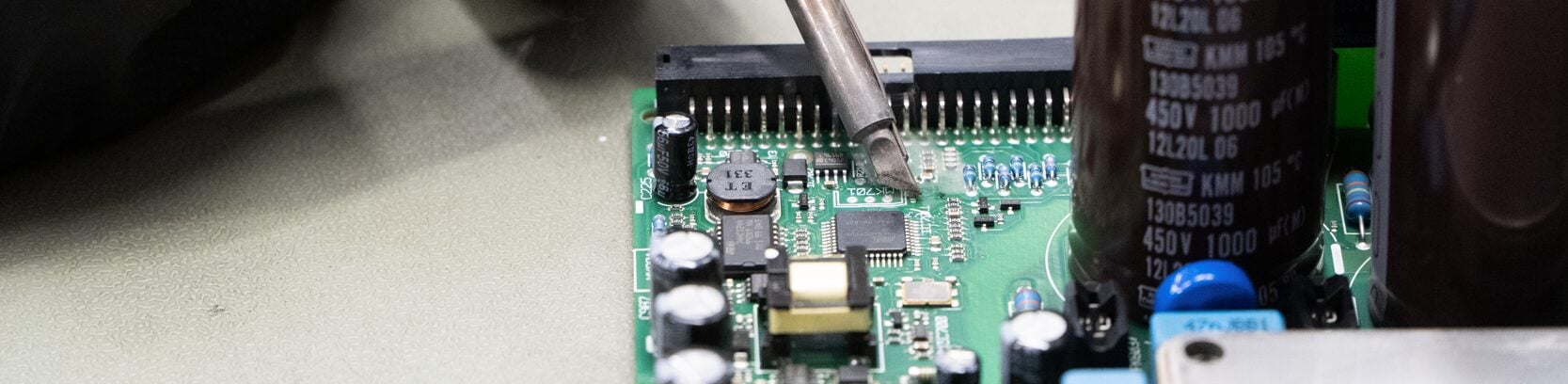

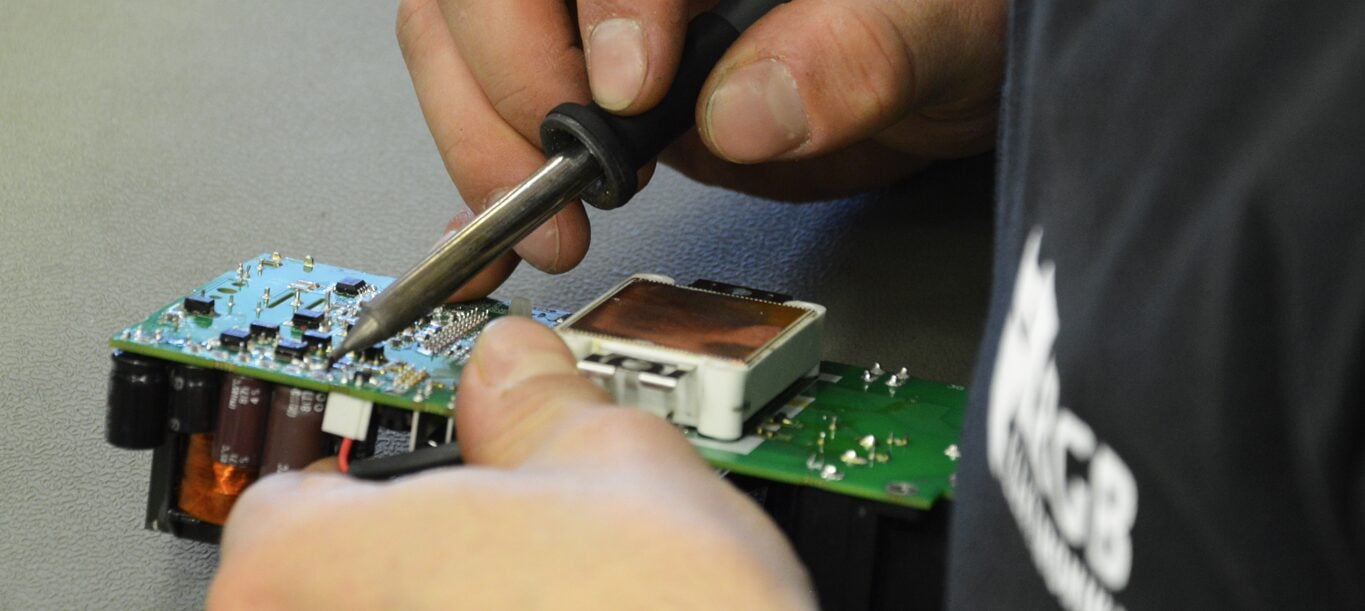

Each inverter is analyzed in detail with advanced diagnostic tools before repair, which allows us to accurately locate the problem, whether it affects a single component or the entire system. Defective components such as the Danfoss inverter are replaced or remanufactured. Once the repair is completed, the device is tested under load and under near-real conditions on proprietary test benches.

Inverters are used in various industrial sectors, including:

- Industrial automation

- Robotics

- Transportation and logistics

- Food industry

- Automotive industry

- Textile industry

- Pharmaceutical industry

Danfoss inverter not starting?

Find out what steps to take to quickly diagnose the problem and get your device back up and running.

Learn more

How does the Danfoss inverter repair at Neethsel HK work?

Have it repaired

To request a repair quote, please fill out the form and a Neethsel HK Account Manager will contact you as soon as possible.

Verification of the device being repaired at Neethsel HK

The appliance repair quote takes up to 7 working days and is free of charge. We also have a 24-hour valuation option for an additional fee of PLN 450 net.

Repair offer

We send the repair offer in the form of a pdf document, which includes information on repair time, price and warranty.

Repair and testing

RGB’s service team will restore the device to full operation and subject it to quality control during load tests or environmental simulations.

Neethsel HK Quality Guarantee

We provide a warranty of up to 24 months usually for the entire device, not only for the sections under repair. The warranty also covers devices withdrawn from production.

Delivery of a working device

The fully operational and securely packaged device can be picked up in person or we will ship it to the specified address. Delivery is also possible, out of hours, available for a fee.

Transparent process

We care about the smooth flow of goods and services, so we monitor the condition of each piece of equipment, the course of repair or the method and quality of packaging, so as to eliminate downtime and damage in transit

Don’t throw it away. Fix it!

At Neethsel HK, we restore Danfoss inverters to full performance, extending their service life and improving the reliability of operation in industrial automation systems. Through thorough testing, detailed diagnostics and expert remanufacturing, devices such as Danfoss inverter regain performance like new. If you want to save money and care for the environment, it is worth betting on expert service and remanufacturing instead of costly replacement. Regular maintenance and inspection is a guarantee of stable and trouble-free operation.

Take advantage of our Danfoss inverter service and receive a fully operational device.

Fill out the “Request Repair” form and get fast service. The more information you provide, the more efficiently we will prepare a quote and carry out the repair of the inverter.

Hotline Service: +852-3008 7967

Email: [email protected]

Danfoss inverter diagnostics

Danfoss inverter repair is an important part of ensuring the smooth operation of industrial automation systems. The Danfoss VLT 2800 inverter, or frequency converter, controls the speed of electric motors by converting direct voltage to alternating voltage. Failure of the inverter or the occurrence of an error can cause downtime and loss of production, so a quick repair at Neethsel HK is important for business continuity. Our service accurately identifies faults and effectively removes them, restoring equipment to full operation. Regular maintenance and repair of Danfoss inverters reduces the risk of failure and maintains the stability of industrial machinery.

Typical Danfoss inverter maintenance services include:

- Replacement of electrolytic capacitors responsible for voltage stabilization.

- Locating and troubleshooting communication failures between modules and host systems.

- Repairing problems in the control systems that affect the proper operation of the inverter.

- Service and reconditioning of cooling systems, including replacement of heatsinks and fans.

- Repair of power sections, including components such as IGBT transistors and power modules.

- Repair of inverter temperature control systems, including sensors and overheating protection systems.

- Service of DC/DC converters in inverters that manage the internal power supply.

- Repair of the capacitor precharging system (soft start).