BAUMÜLLER service and repair

We repair and remanufacture BAUMULLER series components: drives and power supplies BKF12, BKD6, TAC, BUL, BUS, BUM, BUH2, BUH-4, b maXX 1000, b maXX 2000, b maXX 3000, b maXX 4000, b maXX 5000, servo motors DA, DS, DSC, DSD, DSG, DS2, DST2, DSH1, DSP1, DSC1, and spindles VDOKG, VDOKFF, GNAFF.

Neethsel HK offers professional service for Baumüller equipment, including services such as:

- Service of Baumüller servo drives

- Baumüller inverter repair

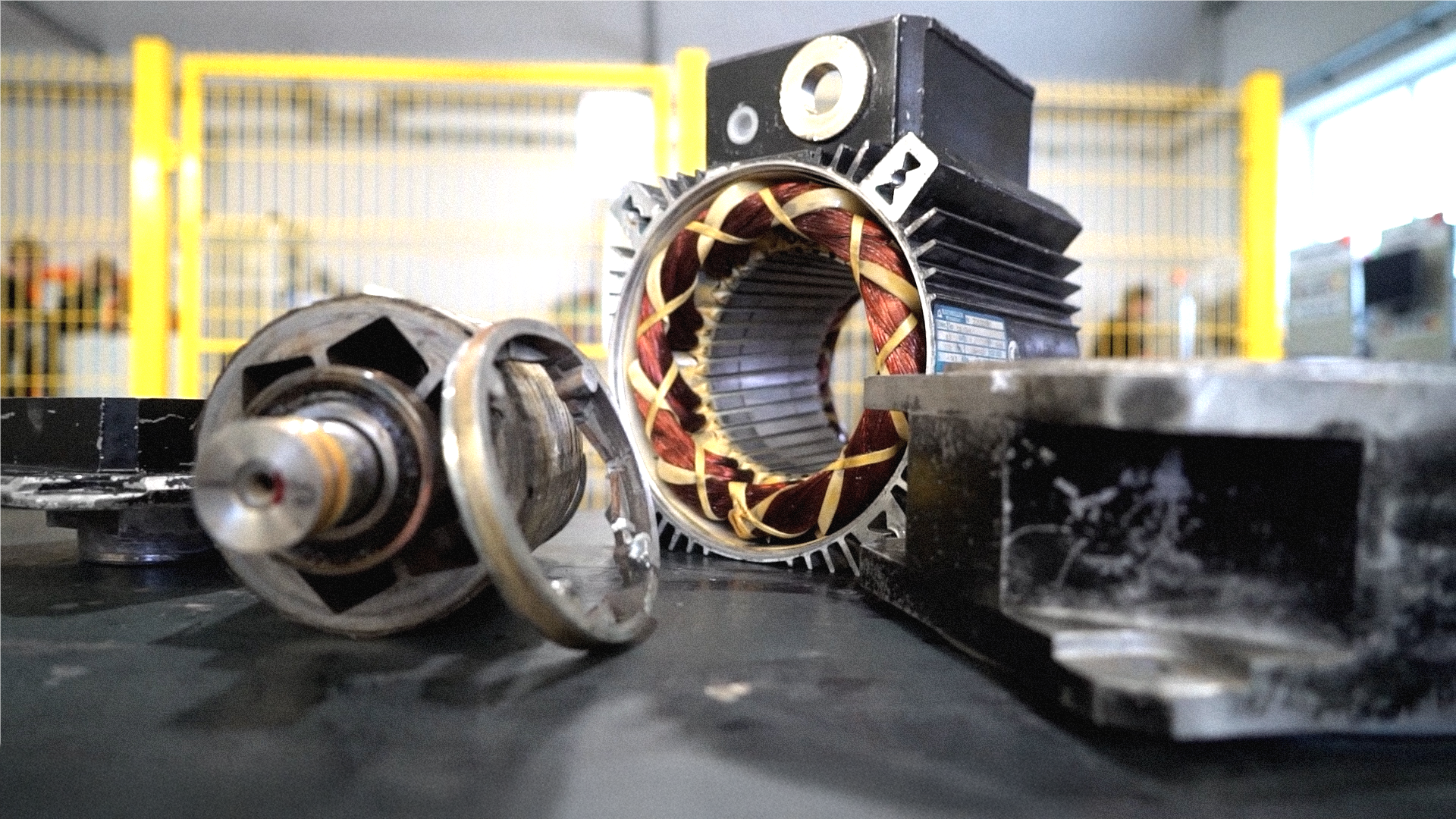

- Baumüller servomotor service

- Baumüller induction motor service

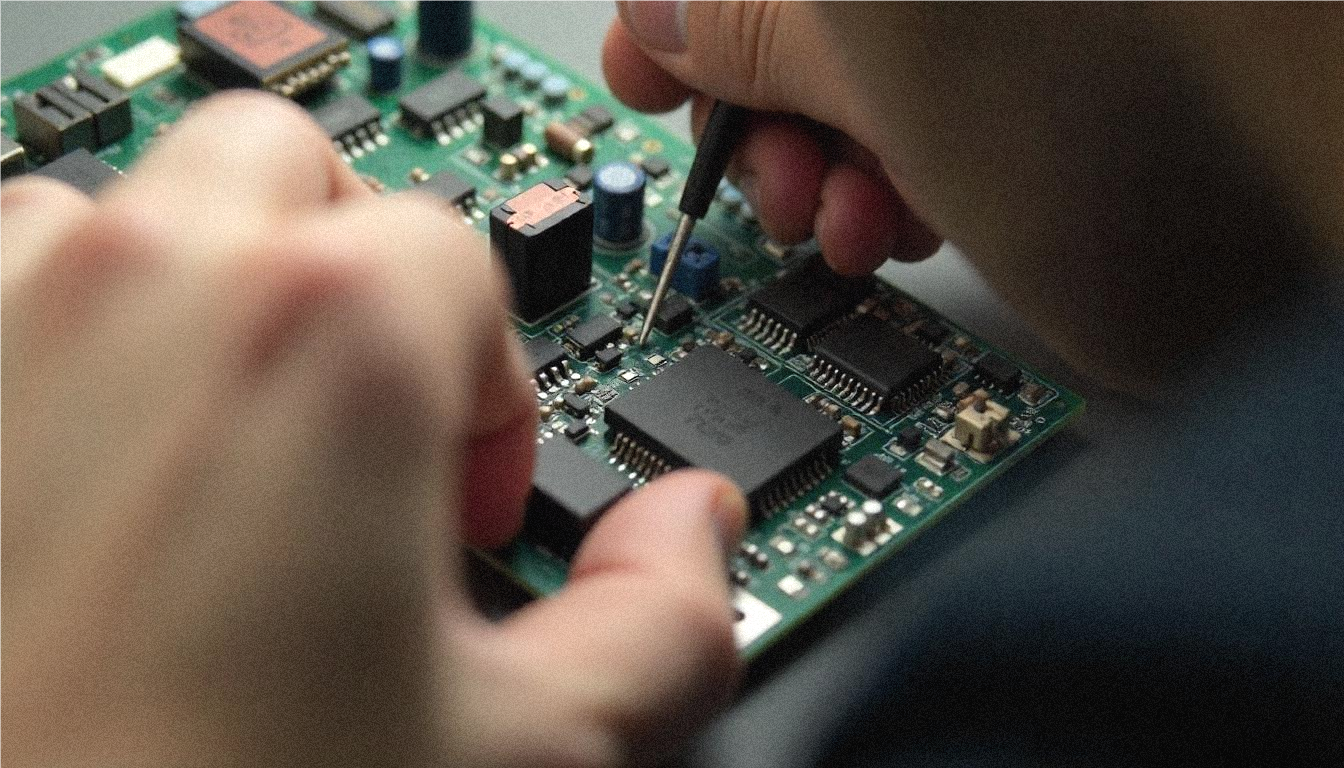

- Repair of Baumüller servo control card

- Baumüller servo motor reconditioning

Device diagnostics

Express repair

Functional tests

Baumüller Inverter Repair

Neethsel HK Limited has been supporting industrial plants for 25 years, offering specialized services in the repair of automation devices. Our power electronics service includes the repair of Baumüller inverters and servomotors – from regeneration, through replacement of worn components, to testing on dedicated stands.

Our technical team also performs comprehensive repairs of frequency converters, servodrives, and control cards, offering fixed prices and quick turnaround times.

As part of our services, we offer precise dynamic balancing, which is a key element of the service process to increase the reliability of the device. We also perform rotor and stator testing up to 6kV and carry out technical parameterization and modernization of drive systems.

What sets Neethsel HK service apart

We provide professional service for Baumüller industrial equipment:

- For repairs we use high quality spare parts, which come from our warehouse located in Hong Kong

- After repairs, we carry out functional tests of inverters, servo drives and servomotors on dedicated test stands

- We provide short repair times, even up to 1 business day

- We repair and remanufacture discontinued and unavailable devices

- We provide warranty for repair of Baumüller industrial parts equipment up to 24 months

- We serve customers in Hong Kong, Europe and around the world

Have us repair your equipment and pick up a working device

To order repairs, please fill out the online form “Repair quote”. In the description, please provide as much information as possible about the device submitted for repair, which will reduce the time of valuation. You are welcome to contact us.

Hotline Service: +852-3008 7967

Email: [email protected]

Baumüller component characteristics:

Baumüller inverter

An inverter (inverter) is a device that converts direct current to alternating current, allowing voltage and frequency regulation.

Advantages of Baumüller inverters:

- Provide protection for motors against overloads and short circuits.

- Optimize production processes by adjusting operating parameters to meet current needs, which improves industrial process management and increases efficiency.

- Integration with control systems to enable monitoring, automation and advanced real-time control.

Baumüller Servomotor

A servomotor is an actuator that is part of a servo system and is responsible for precise motion control in automation systems. It provides accurate speed and position control in real time.

Advantages of Baumüller servo motors:

- Versatility and applicability in a variety of environments.

- Thermal stability, enabling operation over a wide temperature range (from -40°C to +120°C).

- A wide speed range, providing speeds from a few revolutions per minute to high speeds, ideal for systems such as CNC.

Baumüller servo motor

A servo motor is an actuator that precisely controls speed and position based on control signals. It is used in applications requiring high accuracy and dynamic response.

Advantages of Baumüller servo motors:

- High energy efficiency, which contributes to reducing operating costs and improving overall system efficiency.

- The longevity of the equipment, due to the high quality of materials, ensures its reliability, and in the event of failure, repair restores full functionality.

- Compatibility with various control systems

Baumüller brand equipment is used in many industries, including:

- Industrial automation

- Robotics

- Transportation and logistics

- Food industry

- Automotive industry

- Textile industry

- Pharmaceutical industry

How does the service delivery process work at Neethsel HK?

Have it repaired

To request a repair quote, please fill out the form and a Neethsel HK Account Manager will contact you as soon as possible.

The diagnostics of the device at Neethsel HK

You will receive a free of charge repair quotation within 7 working days. Alternatively, there is an option of receiving the quotation within 24 hours for an additional fee of 110 EUR.

Repair offer

We send the repair offer in the form of a pdf document, which includes information on repair time, price and warranty.

Repair and testing

RGB’s service team will restore the device to full operation and subject it to quality control during load tests or environmental simulations.

Neethsel HK Quality Guarantee

We provide a warranty of up to 24 months usually for the entire device, not just the sections under repair. The warranty also covers discontinued equipment.

Delivery of a working device

Fully operational and securely packaged, you can pick up the device in person or we will ship it to your address. Delivery is also possible, out of hours, available for a fee.

Transparent process

We ensure smooth flow of goods and services by monitoring the status of each device, the progress of repairs, and the method and quality of packaging to eliminate downtime and transportation damage.

We conduct detailed functional tests of Baumüller devices

With specialized test benches, we simulate the natural operating conditions of Baumüller equipment, allowing us to accurately assess its performance and reliability before it is put back into operation.

- Baumüller test bed

Sustainability at Neethsel HK

At Neethsel HK, sustainability is an integral part of the business. Using refurbished equipment helps to reduce industrial waste and reduce the negative impact on the environment. We take care to minimize the negative impact on the environment while guaranteeing the high quality of reconditioned equipment.

Let us repair your device and you will receive it in working order

To order repairs, please fill out the online form “Repair quote”. In the description, please provide as much information as possible about the device submitted for repair, which will reduce the time of valuation. You are welcome to contact us.

Hotline Service: +852-3008 7967

Email: [email protected]

The most common defects in BAUMÜLLER equipment:

- Failure of IGBT modules in inverters

- Damaged braking resistors

- Communication errors in servo controllers

- Overheating of control systems

- Damage to power transistors in inverters

- Abnormal signals from temperature or voltage sensors in monitoring systems

- Damage to filter capacitors in power supplies

- Irregular operation of inverters

- Problems with servo encoders

- Display errors on operator panels

- Interruptions in current circuits in servo drives

Check which BAUMÜLLER models we repair

| Producer | Product Categories | Models |

|---|---|---|

| BAUMÜLLER | Servomotors | DS71-M |

| BAUMÜLLER | Servomotors | DSG71-M BR.24V |

| BAUMÜLLER | Servomotors | DSOG71-K |

| BAUMÜLLER | Servomotors | DS100K35 |

| BAUMÜLLER | Servomotors | DSDG100M64U30-5 |

| BAUMÜLLER | Servomotors | DSG56-L BR.24V |

| BAUMÜLLER | Servomotors | DSF200M54W27-5 |

| BAUMÜLLER | Servomotors | LIOG71-M |

| BAUMÜLLER | Servomotors | DS56-B |

| BAUMÜLLER | Servomotors | DSF132M54W255UL |

| BAUMÜLLER | Servomotors | DSFF200M54W15-5 |

| BAUMÜLLER | Servomotors | DSFF200K54W15-5 |

| BAUMÜLLER | Servomotors | DSOG100L35 |

| BAUMÜLLER | Servomotors | DAF100M54T10-5 |

| BAUMÜLLER | Servomotors | DSF132L20W25-5 |