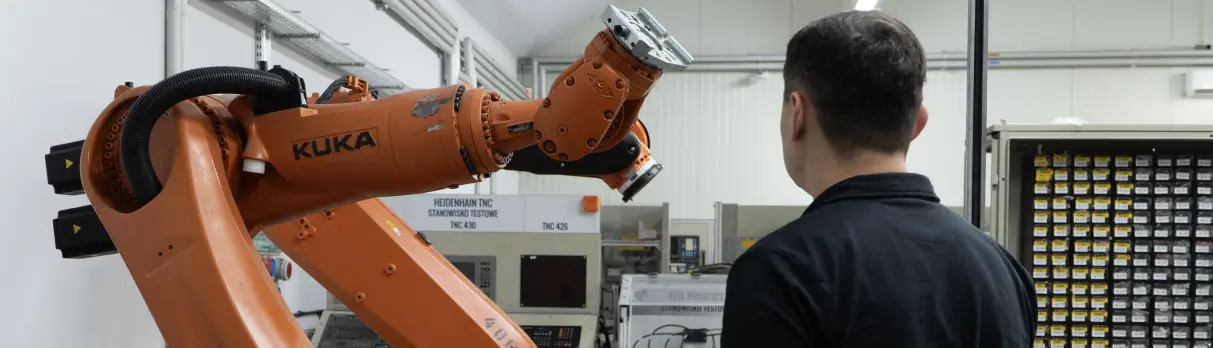

KUKA Robot Repair at Neethsel HK Limited

At Neethsel HK, we repair Kuka KRC, KRC2, KRC4 robot components such as KPC computers, KSD1-16 / KSD1-48 / KSD1-64 / KPP600 drives, KPS-600/20-ESC / KSP600 power supplies, KCP1 / KCP2 / KCP4 smartPAD operator panels, Safety Interface Board (SIB), Resolver Digital Converter (RDC), KUKA System Bus (KSB), DSE-RDW communication cards.

We specialize in repairing components for KUKA robots

- KUKA robot programmers (operator panel, smartPAD, teach pendant, manipulator), including: KUKA KCP1, KUKA KCP2, KUKA smartPAD

- KUKA drive controllers (KUKA inverter repair) among others:

KUKA PM6-600, KUKA KSD1 and KUKA KSP. - Power supplies, including repair of KUKA power supplies: KPS and KPP, and repair of KUKA low-voltage power supplies: KPS

- KUKA industrial computers among others: KUKA KC1, KUKA KC2, KUKA KC4

- KUKA servo motors include: 1FK

- KUKA ESC safety systems

- KUKA cards include: KUKA RDW, KUKA MFC3, KUKA KVG

Device diagnostics of KUKA robots

Express repair of KUKA robots

Functional tests of KUKA robots

Industrial Robot Equipment Repair and Service at Neethsel HK Limited

At Neethsel HK Limited, we repair components for KUKA industrial robots, including servomotors, control modules, and teach pendants. Our services include assessing the technical condition, regenerating worn mechanical parts, repairing electronic systems, and restoring full functionality to the equipment. Thanks to extensive experience with KUKA technology, our repairs are carried out efficiently and in accordance with the manufacturer’s specifications.

What sets Neethsel HK service apart

We provide professional service for KUKA industrial robots by repairing robot components such as:

- For repairs we use high quality spare parts, which come from our warehouse located in Hong Kong

- We conduct functional tests of servo amplifiers, industrial computers and teach pendants directly on the robot

- We provide short repair times, up to 4h

- We provide a guarantee for the repair of KUKA equipment up to 24mc

- We repair and remanufacture discontinued and unavailable devices

- We serve customers in Hong Kong, Europe and around the world

Have us repair your equipment and pick up a working device even in 24 hour

To order repairs, please fill out the online form “Repair Quote”. In the description, please provide as much information as possible about the device being ordered for repair, which will reduce the time for the quote. You are welcome.

Hotline Service: +852-3008 7967

Email: [email protected]

Characteristics of KUKA operator panels

High-resolution touchscreen

- Intuitive user interface supports quick programming and easy monitoring of robot performance

Precision motion control

in six axes

- Allows accurate definition of robot trajectory in advanced applications

Integration with automation systems

- KUKA panels work with SCADA software, PLCs and CNC systems, making them a versatile tool in production automation

Operator panel repair technologies

Work under the microscope

KUKA robot repair, KUKA inverter repair and KUKA smartPAD repair require the use of industrial microscopes, due to the presence of advanced electronic circuits with small dimensions. This technique allows:

- Localization of microdamage in circuits

- Precision soldering of SMD components

- Protection of adjacent components during servicing

The use of microscopes minimizes the risk of errors and allows even complex defects to be fully repaired.

3D printing of fragments and parts of enclosures

3D printing technology perfectly complements processes such as a damaged teach pendant or repairing a robotic rod. It makes precise reproduction possible:

- Missing housing components

- Internal components, such as handles or mounts

The high-quality materials used in 3D printing provide durability and aesthetics comparable to original parts. In addition, 3D printing makes it possible to become independent of the availability of spare parts, which speeds up repairs.

Repair of operator panels in dust-free conditions

Repair of KUKA production robots, repair of KUKA industrial computers and repair of KUKA operator panels in Neethsel HK is done under controlled conditions of dust-free environment, which ensures:

- Protection of sensitive electronic components

- Increase durability and reliability by eliminating factors that can affect their operation

We conduct functional tests of KUKA robot components

We have test benches that allow us to test every component of a KUKA robot, including models no longer available on the market and in the manufacturer’s offer.

- Test stand for KUKA KR C4

- Test stand for KUKA KR C2

How does the service delivery process work at Neethsel HK?

Have it repaired

To request a repair quote, please fill out the form and a Neethsel HK Account Manager will contact you as soon as possible.

The diagnostics of the device at Neethsel HK

You will receive a free of charge repair quotation within 7 working days. Alternatively, there is an option of receiving the quotation within 24 hours for an additional fee of 110 EUR.

Repair offer

We send the repair offer in the form of a pdf document, which includes information on repair time, price and warranty.

Repair and testing

RGB’s service team will restore the device to full operation and subject it to quality control during load tests or environmental simulations.

Neethsel HK Quality Guarantee

We provide a warranty of up to 24 months usually for the entire device, not just the sections under repair. The warranty also covers discontinued equipment.

Delivery of a working device

Fully operational and securely packaged, you can pick up the device in person or we will ship it to your address. Delivery is also possible, out of hours, available for a fee.

Transparent process

We ensure smooth flow of goods and services by monitoring the status of each device, the progress of repairs, and the method and quality of packaging to eliminate downtime and transportation damage.

Sustainability at Neethsel HK

At Neethsel HK, sustainability plays a very important role in the service of advanced equipment such as the KUKA handheld programmer. This approach combines environmental care with high-quality remanufacturing of industrial automation equipment, supporting the efficiency of our customers’ production processes while reducing environmental impact. According to this principle, KUKA servo motor remanufacturing and KUKA servo mechanism remanufacturing are the main activities of the Neethsel HK service.

Have us repair your equipment and pick up a working device

To order repairs, please fill out the online form “Repair Quote”. In the description, please provide as much information as possible about the device being ordered for repair, which will reduce the time for the quote. You are welcome.

Hotline Service: +852-3008 7967

Email: [email protected]

The most common malfunctions of KUKA robots that we successfully repair

- Cracked die in teach pendant

- Axle overload

- Robot crashes during startup

- “Unknown Operation Mode” message.

- Robot stops during operation and informs you that ratin Mode motors are off

- No backlighting on smartPAD

- Unfunctional buttons in teach penden

- Damaged touch in smartPAD panel

- Operator panel cable damaged

- Damaged keyboard in teach pendant

- Defective emergency STOP button in teach pendant

- Damaged mouse/manipulator in teach pendant

- Computer does not boot

- System Resetting

- Memory module damage

- Damaged hard drive

- MFC 3 errors

- Damaged data cable

- Drive module synchronization errors

KUKA materials to download

Professional service of equipment and components for KUKA robots

Among others, the following models:

| Producer | Product category | Models |

|---|---|---|

| KUKA | Teach Pendant | 00-168-334 |

| KUKA | Teach Pendant | KCP2 00-130-547 |

| KUKA | Teach Pendant | 00-291-556 |

| KUKA | Teach Pendant | KCP4 00-168-334 |

| KUKA | Teach Pendant | 00-107-263 |

| KUKA | Teach Pendant | KSD1-16 00-122-285 |

| KUKA | Teach Pendant | 00-131-239 |

| KUKA | Teach Pendant | 00-130-547 |

| KUKA | Teach Pendant | 00-216-801 |

| KUKA | Teach Pendant | 69-000-398 |

| KUKA | Teach Pendant | 00-168-334 KUKA |

| KUKA | Teach Pendant | 00-312-962 |

| KUKA | Teach Pendant | KRC4 00-216-801 |

| KUKA | Teach Pendant | 00-189-002 |

| KUKA | Teach Pendant | KCP2 STD.ED05 00-130-547 |

Find out which series of KUKA products we support for repairs:

- KUKA KCP4 smartPAD

- KUKA KCP2 Teach Pendant

- KUKA KPS Power Supply Unit

- KUKA KRC2

- KUKA KRC4

- KUKA KSD Servo Drive

- KUKA KCP1 Teach Pendant