Regeneration of spindles at Neethsel HK Electronika

At Neethsel HK, we service spindles, offering the following: repair of the 1PH series by Siemens; the 2AD series by Rexroth/Indramat; and the KNS, KRS series by Perske.

Call

Neethsel HK offers professional spindle service from leading brands such as:

- ABB spindle service

- Allen-Bradley spindle service

- Baumuller spindle service

- Beckhoff spindle repair

- Bosch Rexroth spindle repair

- B&R Automation spindle repair

- Control Techniques Spindle Repair

- Danfoss spindle repair

- Repair of ELAU and Schneider Electric spindles

- FANUC spindle repair

- HEIDENHAIN spindle repair

- Indramat spindle repair

- KEB spindle repair

- KEBA spindle repair

- KUKA spindle repair

- Lenze spindle repair

- Mitsubishi Electric spindle repair

- Repair of OKUMA spindles

- Rexroth spindle repair

- Repair of SEW EURODRIVE spindles

- Siemens spindle repair

- TRUMPF spindle repair

- YASKAWA spindle regeneration

Device diagnostics of spindles

Express repair of spindles

Functional tests of spindles

Spindle Repair and Regeneration

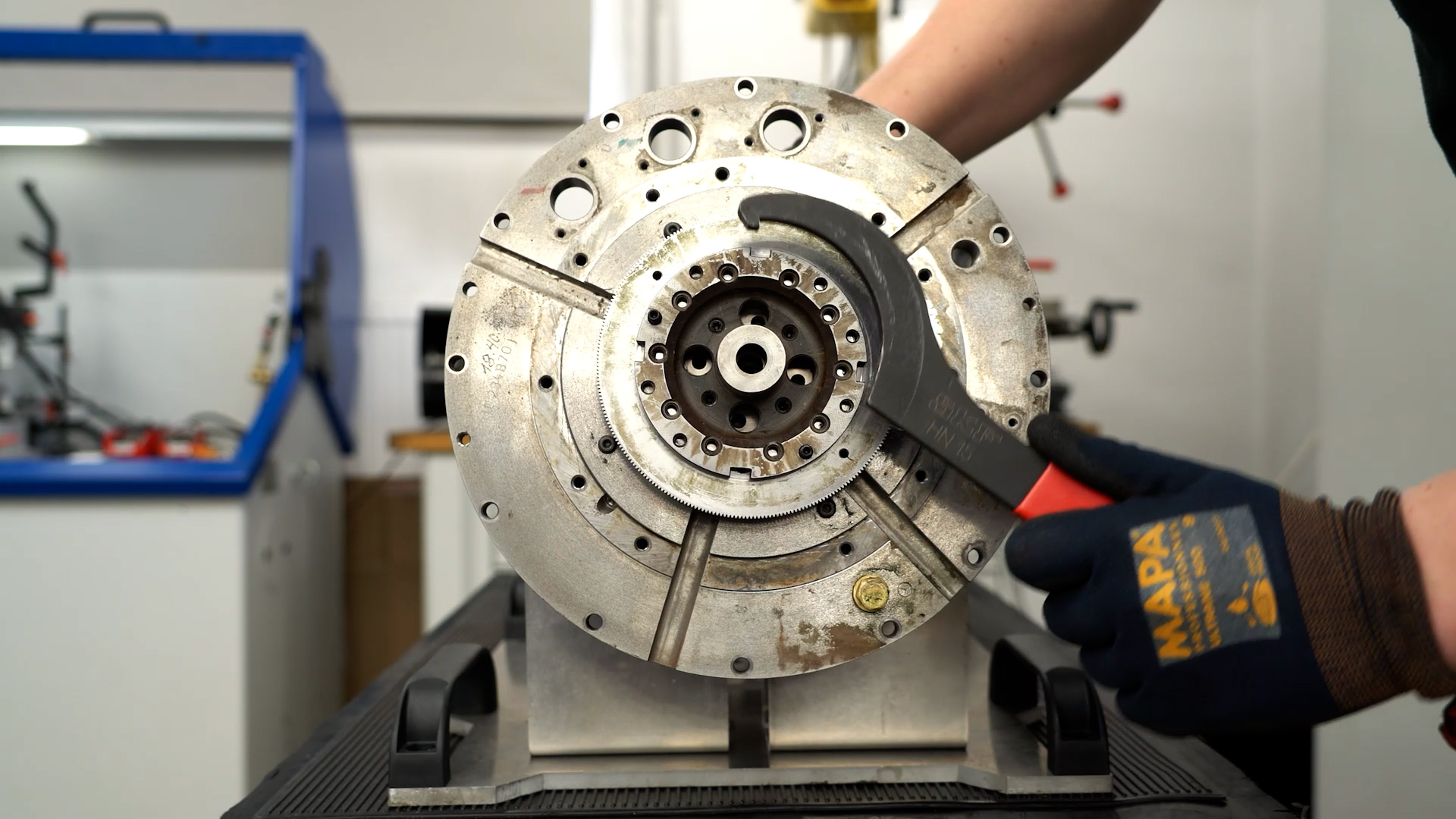

Spindle repair at Neethsel HK Limited includes full disassembly of the unit, assessment of mechanical and electrical condition, replacement of worn bearings, seals, and regeneration or replacement of encoders and rotation sensors. We also conduct axial and radial runout measurements, dynamic balancing, and testing under conditions simulating machine operation.

Contact us

What sets Neethsel HK service apart

We provide professional spindle service:

- For repair we use high quality spare parts that come from our warehouse located in Hong Kong

- After repairs, we carry out functional tests of spindles on dedicated test stands

- We provide short repair times, even up to 1 business day

- We repair and remanufacture equipment withdrawn from production and not available on the market

- We provide warranty for repair of industrial parts equipment up to 24 months

- We serve customers in Poland, Europe as well as from all over the world

Have us repair your damaged spindle and receive a working device

To order spindle repair, please fill out the online form “order repair”. In the description, please provide as much information as possible about the device you are requesting to be repaired, which will reduce the time for the quote. You are welcome.

Hotline Service: +852-3008 7967

Email: [email protected]

Spindle repair characteristics:

Spindle repair at Neethsel HK involves the precise restoration of the device’s functionality by reconditioning damaged components and replacing mechanical and electronic components, with high technological standards. Spindle failure can include bearing failure, wear on rotating components, damage to cooling systems or failure of electrical circuits. Spindle failure can also lead to problems with synchronization of operation, which requires careful analysis and repair of electronic and mechanical circuits to ensure full functionality of the device after reconditioning. The repair process is carried out with quality standards and guarantees of operational performance under harsh industrial conditions.

We conduct detailed functional tests of the spindles:

We conduct detailed functional tests of spindles, which include simulation of actual operating conditions of the device, checking parameters such as speed, stability, torque and temperature during loading. These tests allow us to evaluate the full performance of the spindle, verify the operation of mechanical and electronic systems, and confirm compliance with safety and quality standards. Through precise testing procedures, we ensure that the repaired spindle operates with full efficiency and reliability under demanding industrial conditions.

Spindles are used in many industries, including:

- Industrial automation

- Robotics

- Transportation and logistics

- Food industry

- Automotive industry

- Textile industry

- Pharmaceutical industry

How does the spindle repair work at Neethsel HK?

Have it repaired

To request a repair quote, please fill out the form and a Neethsel HK Account Manager will contact you as soon as possible.

The diagnostics of the device at Neethsel HK

You will receive a free of charge repair quotation within 7 working days. Alternatively, there is an option of receiving the quotation within 24 hours for an additional fee of 110 EUR.

Repair offer

We send the repair offer in the form of a pdf document, which includes information on repair time, price and warranty.

Repair and testing

RGB’s service team will restore the device to full operation and subject it to quality control during load tests or environmental simulations.

Neethsel HK Quality Guarantee

We provide a warranty of up to 24 months usually for the entire device, not just the sections under repair. The warranty also covers discontinued equipment.

Delivery of a working device

Fully operational and securely packaged, you can pick up the device in person or we will ship it to your address. Delivery is also possible, out of hours, available for a fee.

Transparent process

We ensure smooth flow of goods and services by monitoring the status of each device, the progress of repairs, and the method and quality of packaging to eliminate downtime and transportation damage.

Don’t throw it away. Repair!

At Neethsel HK, we restore spindles to full working order, extending their life and reducing replacement costs. With professional repair and load testing, your equipment can work like new. Take care of your equipment and the environment – choose remanufacturing over replacement!

Have your spindle repaired by us and receive a working device even

To order spindle repair, please fill out the online form “order repair”. In the description, please provide as much information as possible about the device you are requesting to be repaired, which will reduce the time for the quote. You are welcome.

Hotline Service: +852-3008 7967

Email: [email protected]

Most common spindle failures:

- Bearing damage

- Wrong speed

- Improper operation of the spindle motor

- High operating temperature

- Improper spindle calibration

- Damage to couplings

- Cooling system failure

- Vibration and instability during rotation

- Encoder failure

- Power system error

- Contamination of the lubrication system

- Spindle electrical failure

- Incorrect speed setting

- Destruction of wire insulation

- Mechanical damage (such as cracks)

- Spindle overload

- Spindle controller failure

- Engine overheating

- Internal contamination of spindle components