- Neethsel HK Limited

- Frequently Asked Questions

Frequently asked

questions

General

Most of the devices and products from our store come with a 2-year warranty. The warranty covers not only new products, but also refurbished and used equipment. About the length of the granted warranty, we inform in the offer, which we always send to the customer for approval.

We check the products we ship before they are shipped, hence we have different shipping dates, which we inform you of after you place your order. We need to make sure that the equipment we deliver is fully functional. We ship checked or new equipment up to 3 business days.

For orders placed with Neethsel HK on prepayment, we send a proforma invoice to the email address provided by the customer.

We would like to remind you that the purchase at Neethsel HK is only available for companies. We issue an invoice for each purchase. We do not provide sales, purchase service for individuals.

Yes, it is possible to pick up your order in person at the customer service point by appointment.

We try not to substitute unless it is explicitly requested by the customer. We always use original parts sourced from trusted suppliers. This approach ensures that when returning the repaired and fully functional device, we can guarantee its operation for a long time.

You can check the status of your order on the store yourself in the “Order Status” tab. You can also contact us by email or hotline.

Purchase

We do not buy products from private individuals. We buy equipment only from entities that can issue a VAT invoice.

Unfortunately, we do not buy equipment in its entirety. We are interested in individual components or subassemblies. If you have an industrial robot for sale for parts, please feel free to contact us.

We send responses within one business day, but very often we manage to respond within a few hours.

We do not carry out waste disposal. We buy back valuable devices that can be reused recovering their full functionality.

Yes, the device can be delivered to our warehouse in Hong Kong. We are open weekdays from 7:00 am to 4:00 pm.

Repair of KUKA robots

To repair a damaged KUKA robot controller, you must first locate where the damaged robot panel is. It can be, for example, a broken wire, damaged insulation or plug. If the plug is damaged, it should be replaced according to the wiring diagram. After repair, the cable should be tested for proper operation. If the damage is serious or you do not have the necessary experience, it is best to return the operator panel to the KUKA industrial robot service at Neethsel HK.

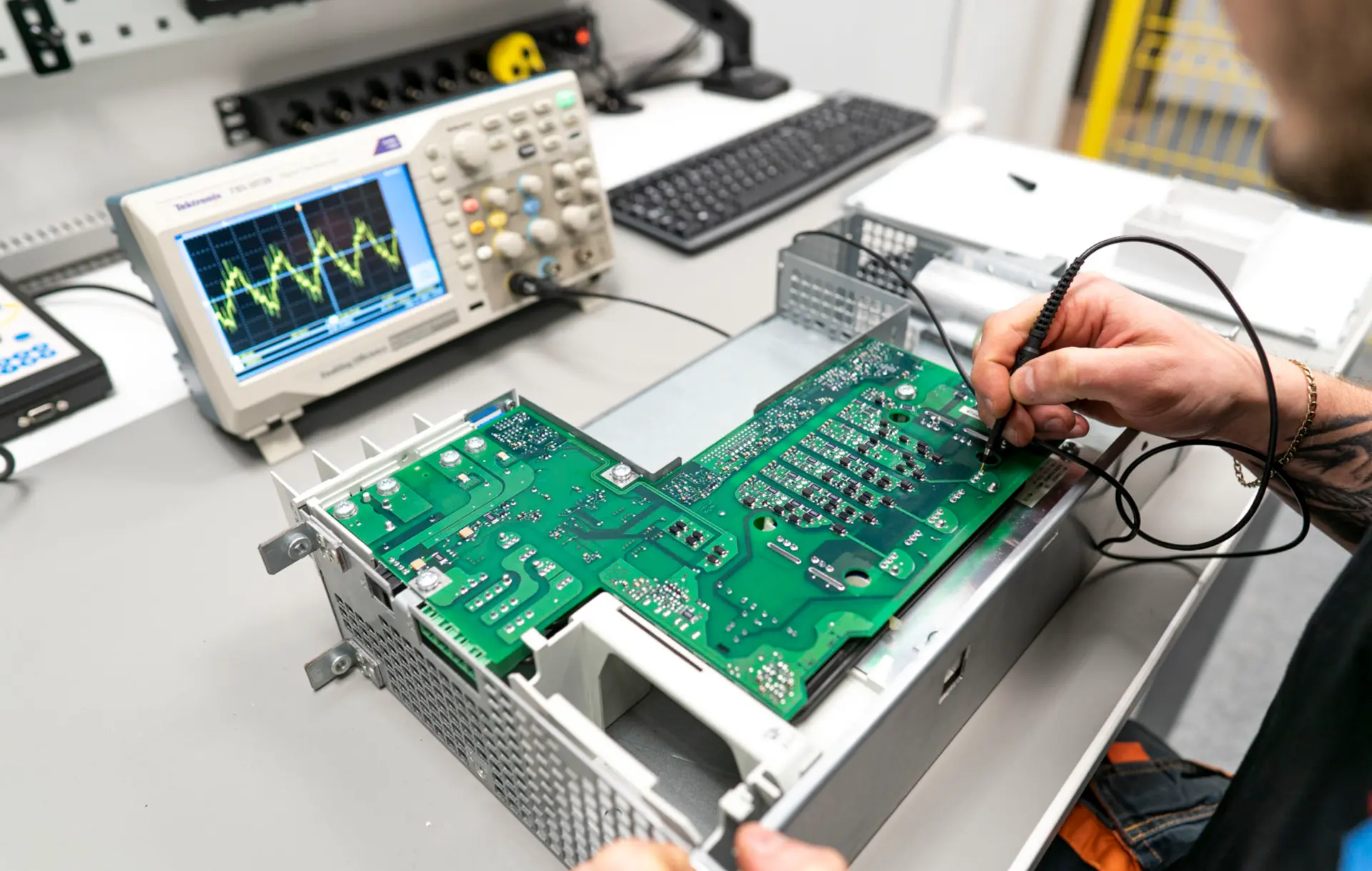

Repair of KUKA inverters involves fault determination, replacement of damaged components and functional testing. The process begins by identifying faults using tools such as multimeters, oscilloscopes or specialized software. Typical problems include defective power modules, capacitors, controls or communication errors. Once a faulty part is detected, it is replaced with an original or compatible replacement. KUKA inverter repair is completed with real-world testing to check its performance. For full reliability, it is recommended that the repair be carried out by a KUKA inverter service, such as Neethsel HK Limited service.

Replacing a broken die in a KUKA teach pendants requires precision and the right tools. The process begins with turning off the robot and disconnecting the operator panel. Then the teach pendant’s housing must be carefully opened to access the die. Once the damaged component is identified, the broken die is removed and a new die is installed in reverse order. After closing the case, the panel should be tested to ensure that the new die works properly. For safety and quality assurance, the mobile pad service offered by Neethsel HK is recommended.

Service Neethsel HK, thanks to the long experience of the team, offers repair of KUKA KR C1 operator panels in the price range of 5138 PLN – 6423 PLN (net). The price is suggested and the final amount depends on the scope of repair.

Yes, we do. Our specialties include KUKA power supply repair KPS and KPP, and KUKA low voltage power supply repair KPS.

KUKA robot rod repair involves finding and fixing faults in the operator panel. Common problems include damage to the touch screen, control buttons, joystick or the cable connecting the rod to the robot. Once the repair is complete, the rod is tested to make sure all functions work properly and safely. For complete reliability, it is recommended to have the repair done at a specialized Neethsel HK service center.

Yes, we provide KUKA industrial robot service, including comprehensive services such as KUKA robot repair and KUKA industrial robot repair. Our team also specializes in tasks that include KUKA production robot repair, providing fast and effective solutions. With experience and access to original parts, we offer the highest standard of service in the field that is KUKA robot repair, regardless of the type of defect. Contact us for more information or to request a repair.

KUKA servo motor remanufacturing involves comprehensively restoring the KUKA servo motor to full efficiency and performance through detailed cleaning, fault-finding and replacement of worn-out components. In the remanufacturing process, we perform activities such as KUKA servo motor repair and KUKA servo motor repair to ensure reliable operation. This includes KUKA servo remanufacturing, including replacement of bearings, seals and other mechanical components. For maximum efficiency, we carry out activities that include KUKA servo motor remanufacturing, ensuring proper balancing and functional testing. As a result, each KUKA servo motor regains its factory parameters and is ready for further operation in an industrial environment.

KUKA industrial computer repair involves finding and fixing faults that may affect the operation of the robot or the entire automation system. As part of a service such as KUKA industrial computer repair, we perform a thorough analysis of the hardware and software, including identification of problems such as smart pad error. Repairs include replacing damaged components (such as disks, RAM modules or power supplies), or repairing motherboards. After the repair, each KUKA industrial computer is tested under conditions simulating actual operation to ensure its reliability and full functionality.

Repair of B&R Automation equipment

B&R Automation’s servo motor repair at Neethsel HK is accomplished through a thorough analysis and identification of damage. The repair process includes replacing worn components such as bearings, motors or electronic components, as well as performance testing after repair. The team of specialists uses the right tools and software to restore the device to full working order, ensuring the quality and precision of the servo motors.

Yes, we repair B&R Automation industrial computers. We offer service that includes repairing damaged hardware components, such as motherboards, power supplies and other electronic components. We also perform tests to make sure the device works properly after repair.

Servo reconditioning in B&R Automation systems involves several steps: condition assessment, replacement of worn or damaged mechanical components (such as bearings, brushes) and electronics (e.g. controllers, sensors). After the repair, tests are carried out, on specially prepared stations, to ensure full functionality and synchronization with the rest of the system.

Repairing B&R Automation inverters is a multi-step process that includes: identifying the problem, disassembling and analyzing damaged components, replacing defective components (e.g. transistors, capacitors) and testing the device for functionality.

Repairing B&R Automation operator panels involves identifying and fixing defects in the electronic and mechanical parts. This can include repairing or replacing displays, repairing the touch system and replacing electronic components responsible for communication with the control system.

Repairs

Devices repaired and sold by us receive up to 24 months of warranty. We inform you about the warranty of each ordered item in the offer presented to you.

We try not to substitute unless it is explicitly requested by the customer. We always use original parts sourced from trusted suppliers. This approach ensures that when returning the repaired and fully functional device, we can guarantee its operation for a long time.

A regional Neethsel HK sales representative will come to you free of charge to pick up the damaged device, or we will pick it up through a transport company. You can also send the device to us personally or send it by courier service.

We provide free estimates for device repairs within 7 business days. We also offer a 24-hour estimation option for an additional fee of 450 PLN.

Yes, we conduct comprehensive functional tests of devices, load tests, and simulate operations under real conditions. We have 36 proprietary control stations and over 50 mobile stations. Every device repaired by us leaves Neethsel HK service tested and fully functional.

Sales

Most of the devices and products from our store come with a 2-year warranty. The warranty covers not only new products, but also refurbished and used equipment. About the length of the granted warranty, we inform in the offer, which we always send to the customer for approval.

In the Neethsel HK Automatics store, we allow you to make payments via PayU, PayPal, via bank transfer or cash on delivery.

Yes, the delivery service of ordered goods in Neethsel HK is chargeable, and the exact delivery costs are calculated when placing the order. However, purchases made for a min. Net PLN 2,500 are exempt from delivery costs, in the currently ongoing promotion.

In such a situation, please contact us and the purchasing department will look for this product among the wide range of suppliers working with our company. If the product you are looking for is in your possession, but has broken down, we can repair it and subject it to detailed tests on our test benches.

An Individual Account Manager is a person in the Neethsel HK team who looks after a particular customer order. This means that it knows everything about the device purchased or the repair being carried out. At any time you can write to the caregiver or call an individual number to get the information you need.

Repair of ELAU and Schneider Electric equipment

ELAU inverter repair at Neethsel HK is carried out in the shortest possible time to minimize downtime for your business. Thanks to our advanced technical facilities, state-of-the-art test benches and a team of experienced specialists, we are able to complete repairs even within one business day.

Schneider Electric inverter repair at Neethsel HK includes a detailed analysis of the malfunction, replacement of damaged components, and testing on advanced workstations that simulate real operating conditions.

Yes, at Neethsel HK we service Elau inverters, including diagnostics, repair and maintenance of the equipment. We use state-of-the-art test benches that allow us to precisely check the operation of the inverter after service.

Schneider Electric servo motor repair at Neethsel HK is a complex process that begins with a thorough failure analysis and verification of the condition of the device. As part of the repair, we replace damaged components such as bearings, encoders or brushes, using original parts or high-quality replacements. Once the repair is completed, the servomotor undergoes detailed testing on dedicated test benches to verify its performance under real operating conditions, ensuring the reliability and full functionality of the device.

Repair of Elau servo motors is worth commissioning to the specialists at Neethsel HK, who have many years of experience in servicing this type of equipment. Our service uses modern technologies, original spare parts and performs detailed tests to ensure full efficiency and reliability of repaired motors. With a fast turnaround process and high quality standards, we minimize downtime for your business.

Elau servo reconditioning involves comprehensive repair and restoration of the device to full performance. The process includes disassembly, thorough diagnostics and replacement of damaged or worn components. After regeneration, the servo undergoes detailed tests on diagnostic benches that simulate real operating conditions to ensure that the device is operating reliably. Remanufacturing helps extend the life of the servo, as well as improve its performance.

Neethsel HK Service, thanks to the long experience of the team, offers repairs in the price range of 3179-10793 PLN (net). The price is suggested and the final amount depends on

Didn’t find the answer to your question?

For more information, we invite you to contact us.

Repair

In our service we repair automation and industrial electronics equipment. We are the only company in Europe to service servo motors in one business day. Service takes place at our headquarters in Hong Kong We give up to two years of warranty on repaired equipment.

Sales

We are one of Europe’s largest distributors of machinery equipment and industrial robots. The Neethsel HK store offers nearly 200,000 new, refurbished, as well as used parts. We operate not only on the Hong Kong market, but sell, find equipment and repair for customers around the world.

Purchase

We buy equipment and industrial automation components that are backlogged in warehouses. We buy back machine parts and individual components, helping to reclaim storage space. We arrange free transportation for each purchased item or device.