Wittmann injection molding machine automation service and robot repair

At Neethsel HK, we repair and service Wittmann industrial equipment, restoring them to full technical efficiency. Among other things, we offer: service of servo drives EU173, EU185, EU252 Prodrive and diagnostics of servo motors of MCS09, MCS12 series.

Call

Service and repair of Wittmann equipment, offered by Neethsel HK, includes services such as:

- Repair of Wittmann hydraulic injection machine components

- Service of components of servo-hydraulic injection molding machines (servo injection molding machines) Wittmann

- Repair of Wittmann robot components

- Wittmann servo control card repair

- Repair of R9 and other Wittmann controllers

- Wittmann reconditioning of AC and servo drives

- Service of servo drives for Wittmann industrial robots

- Wittmann HMI service

Device diagnostics of Wittmann equipment

Express repair of Wittmann equipment

Functional tests of Wittmann equipment

What sets Neethsel HK service apart

We provide professional service and remanufacturing of Wittmann industrial robots:

- For repairs we use high quality spare parts, which come from our warehouse located in Hong Kong

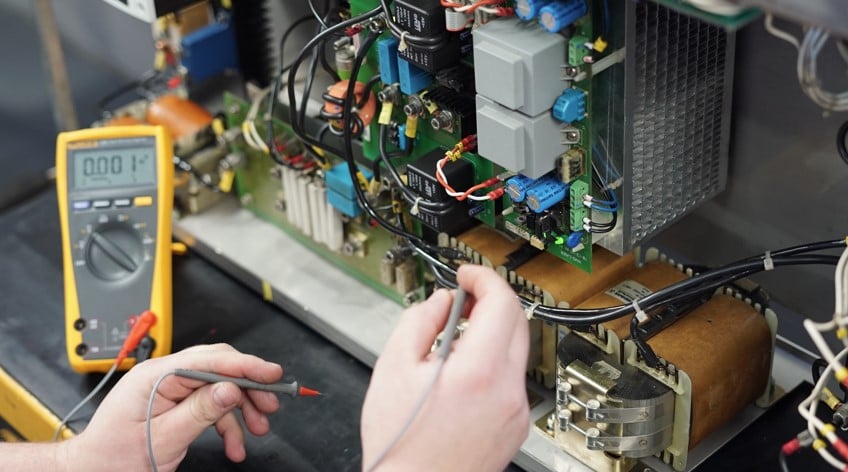

- After repairs, we carry out functional tests of injection molding machines, industrial robots oand drives on dedicated test stands

- We provide short repair and delivery times

- We repair and remanufacture discontinued and unavailable devices

- We provide warranty for repair of industrial parts equipment up to 24 months

- We serve customers in Hong Kong, Europe and around the world

Quick repair of Wittmann robot components

To order the repair of Wittmann robot components, please fill out the online form “Repair quote”. In the description, please provide as much information as possible about the device submitted for repair, which will reduce the time of valuation. We invite

Hotline Service: +852-3008 7967

Email: [email protected]

Repair of Wittmann equipment and components

At Neethsel HK, we carry out repairs to Wittmann robotic components, focusing on components that require special operational attention, which include: injection molding robots and injection molding machines.

The most common services performed at Neethsel HK:

- Wittmann EU-252 repair

- Wittman EU-186 repair

- WX Wittmann robot motor service

- W8 Wittmann robot motor service

Functional testing of Wittmann devices

We conduct detailed functional tests of Wittmann devices – thanks to dedicated test benches, we can accurately assess their performance and stability of operation before sending them back to the customer.

Wittmann brand equipment is used in many industries, including:

- Industrial automation

- Robotics

- Transportation and logistics

- Food industry

- Automotive industry

- Textile industry

- Pharmaceutical industry

Fast repair and service of Wittmann drives

Read more about repairing the brand’s devices.

Learn more

How does the service delivery process work at Neethsel HK?

Have it repaired

To request a repair estimate, please fill out the form and a Neethsel HK Account Manager will contact you as soon as possible.

Verification of the device being repaired at Neethsel HK

The appliance repair quote takes up to 7 working days and is free of charge. We also have a 24-hour valuation option for an additional fee of PLN 450 net.

Repair offer

We send the repair offer in the form of a pdf document, which includes information on repair time, price and warranty.

Repair and testing

RGB’s service team will restore the device to full operation and subject it to quality control during load tests or environmental simulations.

Neethsel HK Quality Guarantee

We provide a warranty of up to 24 months usually for the entire device, not only for the sections under repair. The warranty also covers devices withdrawn from production.

Delivery of a working device

The fully operational and securely packaged device can be picked up in person or we will ship it to the specified address. Delivery is also possible, out of hours, available for a fee.

Transparent process

We care about the smooth flow of goods and services, so we monitor the condition of each piece of equipment, the course of repair or the method and quality of packaging, so as to eliminate downtime and damage in transit

Don’t throw it away. Fix it!

At Neethsel HK, we restore Wittmann devices to full working order, extending their life and increasing their operational reliability in industrial electronics systems. With professional verification, load testing and precise reconditioning, your device can operate like new. If you are concerned about saving money and caring for the environment, rely on a specialized service and choose remanufacturing instead of costly replacement. Maintenance and regular inspection is the key to long and trouble-free operation of equipment in various industries.

Have us repair your inverter and pick up a working device

Fill out the “Request Repair” form and get express service. The more details you provide, the faster we will quote and repair your inverter.

Hotline Service: +852-3008 7967

Email: [email protected]

The most common defects in Wittmann equipment:

- R9 industrial robot controller does not respond to touch

- Drive controller does not start

- CAN communication error (CAN-MODULE COMMUNICATION ERROR)

- Exceeding the time for the axis to reach the position

- Axis encoder errors

- Axis stroke limit exceeded (STROKE LIMIT)

- Leaks in the hydraulic system

- Errors in the B8 control system

- Problems with the lubrication system

Wittman appliance repair

At Neethsel HK, we specialize in servicing Wittmann robot components such as servo drives, controllers, operator panels and other automation system components. Our experience and access to original spare parts allow us to effectively restore full functionality of the equipment, which translates into increased efficiency and reliability of production processes.

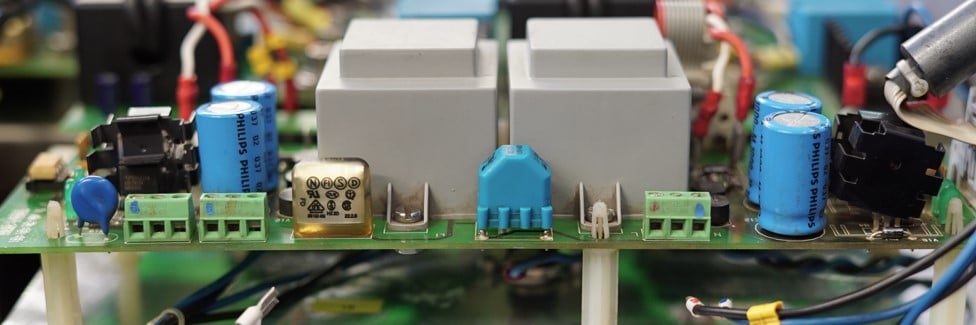

Wittmann EU-186 service includes repair of W-DRIVE 20/30/40A servo drives used in industrial robots. We replace defective components, test the device and provide replacement equipment for the duration of the repair.

Wittmann EU-252 PRODRIVE W4 service is about repairing 11 kW servo drives. We carry out detailed load tests and full reconditioning, restoring the efficiency of the device and ensuring the continuity of system operation.